In order to guarantee aviation safety, the UAS control systems must follow very rigorous validation and traceability processes in each of their manufacturing and assembly processes.

Quality system in control systems

It is vital to maintaining a quality system in the manufacture of control systems for UAS. It depends on whether the unmanned vehicle meets all the security requirements that the aviation authorities (FAA, EASA, AESA, ENAC, DGAC, LBA, AAC…) require UAV manufacturers and operators. The quality plan is a strategic factor and starting point in any aeronautical company. The quality processes of the UAS control systems should focus on fostering continuous control and quality.

Validation of electronics

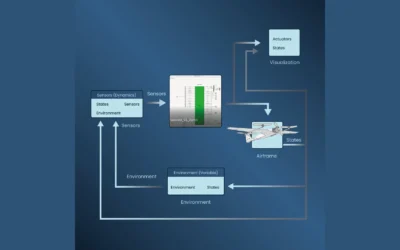

Validation in UAS control systems at hardware level focuses on the operation of electronics and sensors. In this process, the voltage lines and their components are validated, avoiding any voltage overload and which could damage the components. For example, continuity test, voltage test, functional validation of the system, etc.

Traceability of the components

The traceability of the components in the control systems for UAS is the set of procedures that allow knowing the history, location and trajectory of a product or several products along the supply and assembly chain. Recording its manipulations, its composition, the machinery used, its batch, etc.

Veronte Autopilot quality system

Veronte Autopilot is a control system for UAS that complies with an exhaustive quality system. Performing up to four electronic and functional validations before, during, and after their final assembly. And one last before your shipment, to ensure that you have the optimal conditions to be used within a UAS. Always certifying that the results are correct and equivalent in all validations.

Throughout the validation process, all sensors incorporated in the autopilot are checked, ensuring that they are in a valid range of measurement, since if any of them failed at a minimum, the autopilot would be discarded immediately. All traces left in Veronte’s quality management system. With this tool, you can consult all the processes performed during the validation and the life cycle of the product.