In the aircraft industry, the cost of failure is very high, causing significant personal and material damages. For this reason, ensuring the correct operation and calibration of critical devices is crucial in the drone industry. Veronte Autopilot sensors are individually calibrated with equipment that guarantees the quality, safety, and performance of the flight control device according to the high demands in the drone industry.

Calibration is part of our Verification process. To carry it out, Embention has developed the tools and has the suitable equipment to calibrate and apply sensor corrections on every single Veronte Autopilot unit.

This article will describe the importance of calibration and the processes and equipment used to calibrate the Veronte Autopilot static and dynamic pressure sensors.

What is calibration and why is it important?

Calibrating is comparing a device under test, of unknown value, with a reference standard, of known value. The objective of calibration is to determine the error of the device and verify its accuracy. That is, performing a correct calibration allows us to guarantee accurate measurements.

Our pressure calibration equipment

At Embention we use Fluke Calibration equipment, a leading company in the field of calibration instrumentation, whose products ensure precision calibration. Our reference devices are:

- Fluke Pressure Controller and Vacuum Pump.

- Fluke absolute reference module with a range from 2kPa to 100kPa and precision +/- 0.02% of FS. Includes linearity, hysteresis, repeatability, resolution, and temperature effects.

- Fluke relative pressure measurement module with a range from -100 kPa to 200 kPa, accuracy +/- 0.02% of FS

These devices allow the Veronte Autopilot Pressure Sensors to be accurately calibrated throughout their operating range for the safe and precise control of all kind of drones and eVTOL.

Error compensation

Once the comparison between the sensor and the reference has been established, the next step is the calculation of the coefficients for the error compensation in the sensors. The algorithm for calculating the compensation coefficients depends on the type of sensor.

In the case of pressure sensors, a linear adjustment is applied and these coefficients are part of the Autopilot setup.

Veronte Autopilot calibration

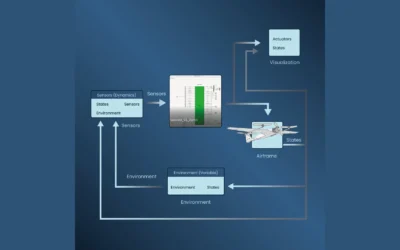

Taking accurate measurements is essential for the correct operation of the Veronte Autopilot. For example, measurements provided by pressure sensors are used to calculate relative speed or height during the drone flight. Therefore, the more precise the measurements, the better the flight control of the device we will achieve. And with it, the safety and performance of the Autopilot is enhanced.