Vibrations play a significant role in the integration of the autopilot in an aircraft. It is essential to pass various simulations and tests in order to find the best insulation and filter combination that guarantees system performance. From Embention, we have summarized the steps to analyze the vibrations in autopilots.

Vibrations and natural frequency of a system

Vibrations in engineering are in some cases a real problem. One of the main obstacles lies in identifying, discriminating and filtering these vibrations in order to isolate the desired dynamics of the system.

The system that, altered from its equilibrium position, vibrates under the action of certain frequencies when it is excited is called “the natural frequency of a system” (or resonant frequency). These repetitions are accompanied by a movement of greater magnitude than non-resonants. Therefore, special attention should be paid to prevent a system resonating in an undesirable way when we are evaluating vibrations in autopilots.

MEMs Sensors

Operating Principle

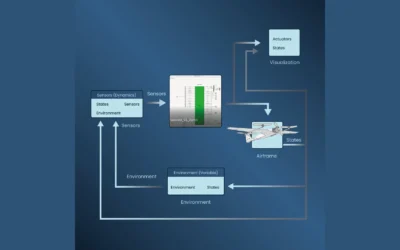

Most UAVs use MEMs sensors (microelectromechanical systems) that provide acceleration and angular velocity measurements. However, they have a disadvantage: their vulnerability to external disturbances such as vibrations. Therefore, it is essential to analyze vibration in autopilots in cases where MEMs sensors are used.

Filtration

Nowadays, filtering is the simplest and most used technique to mitigate the effects of vibrations. It can be of two types:

- Mechanical. Use of absorbent materials that reduce the final disturbance in the UAV inertial sensor.

- Software. Implementation of low-pass filters that discard measures considered invalid because they have a high content in a frequency categorized as vibration.

Veronte’s particular case

Simulations

For the Veronte Autopilot 1x, Embention has performed a series of simulations. Its objective is to determine resonance frequencies in the PCBs where the sensors of our Autopilot are located. With this, the frequencies that must be avoided and isolated are identified. In addition, this type of test permits to define the feasibility of installing Veronte Autopilot in certain aircraft by knowing the operating engine frequencies, rotor, tail rotor…

Tests

After the simulation, it is convenient to test the results obtained on a vibratory platform with selectable frequency. By comparison, we can easily validate the previously built vibration simulation model.

Solutions

With the above results, the material (or the low pass filter implemented) that best isolates the undesirable frequency should be selected and tested. Leaving the aircraft dynamics clean of disturbances.

Conclusion

Vibration analysis is a problem that must be addressed in any mechanical system that integrates any type of mobile structure. As it is the case with the engine of an aircraft. In addition, it is especially critical for those who determine the attitude and direction of the aircraft because of its importance in navigation. In Embention, we study each of the systems in Veronte Autopilot in order to isolate them to the maximum of any unwanted vibration and offer the maximum benefits to our customers.