Mejora la Calidad y Eficiencia de tus Sistemas con Embention

Embention es pionera en la aplicación de estándares de calidad de la industria de la aviación a vehículos autónomos. Siguiendo normativas como DO178C, DO254, STANAG o ISO, Embention es líder en el desarrollo de autopilotos para la certificación de eVTOL y UAVs.

Desde 2007, hemos estado trabajando en el desarrollo de sistemas críticos para aeronaves de ala fija, helicópteros, multirrotores, sistemas híbridos VTOL, barcos, automóviles, parapentes, eVTOL y UAM.

Mejora la Calidad y Eficiencia de tus Sistemas con Embention

Embention es pionera en la aplicación de estándares de calidad de la industria de la aviación a vehículos autónomos. Siguiendo normativas como DO178C, DO254, STANAG o ISO, Embention es líder en el desarrollo de autopilotos para la certificación de eVTOL y UAVs.

Desde 2007, hemos estado trabajando en el desarrollo de sistemas críticos para aeronaves de ala fija, helicópteros, multirrotores, sistemas híbridos VTOL, barcos, automóviles, parapentes, eVTOL y UAM.

Sistema de Gestión de Calidad

La política de calidad de Embention delinea las directrices fundamentales de la empresa, asignando recursos vitales para garantizar que los empleados y las partes interesadas se esfuercen colectivamente por los objetivos compartidos de elevar la calidad del producto y perfeccionar los procedimientos de diseño, desarrollo y producción. Este compromiso se extiende a la mejora continua de las prácticas internas.

El sistema de gestión en Embention se basa en las normas UNE-EN ISO:9001:2015 y UNE-EN 9100:2018. Este marco asegura la integración de los requisitos esenciales para una organización comprometida en los sectores de aviación, espacio y defensa.

En los últimos años, hemos escalado rápidamente en la clasificación de las principales empresas de alta tecnología en las industrias de UAV y UAM, alcanzando metas que inicialmente eran difíciles de imaginar. En Embention, centramos nuestra actividad en el desarrollo de productos innovadores, mejorando permanentemente las capacidades y el rendimiento de nuestros sistemas. La búsqueda de este objetivo se logra con los siguientes valores que impulsan a la empresa:

Calidad

Nuestros productos siguen un estricto proceso de verificación y validación para garantizar la calidad de todos nuestros sistemas.

I+D+i

La empresa invierte considerablemente en investigación y desarrollo para la mejora continua del portafolio de productos.

Fiabilidad

Utilizamos componentes de alta calidad para garantizar la fiabilidad y el rendimiento de nuestros productos.

Seguridad

Nuestros productos se desarrollan de acuerdo con los estándares más estrictos aplicables a la industria aeronáutica, asegurando los más altos niveles de seguridad.

Protección ambiental

Se realizan pruebas ambientales a nuestros productos para verificar que puedan operar de manera efectiva bajo las diversas condiciones ambientales experimentadas durante las operaciones de aviación.

Diseño

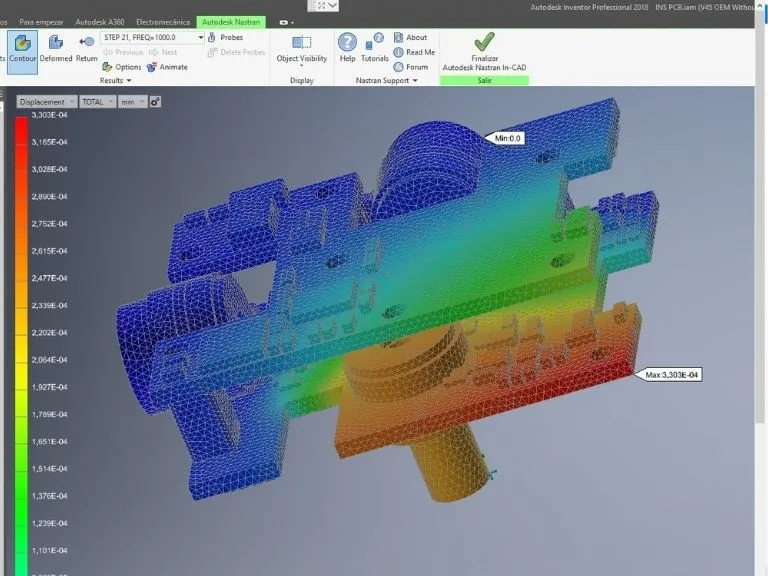

Con más de 16 años en el sector, la calidad ha sido siempre un factor clave en la empresa. En Embention cuidamos todos los detalles del proceso de desarrollo desde su inicio, empezando por el diseño, donde aplicamos la normativa aeronáutica tradicional a los sistemas y componentes para vehículos autónomos.

DO-178C Consideraciones Software para la Certificación de Sistemas y Equipos Embarcados. Define el standard utilizado para demostrar la fiabilidad y aeronavegabilidad en el software embarcado en los sistema de aviónica.

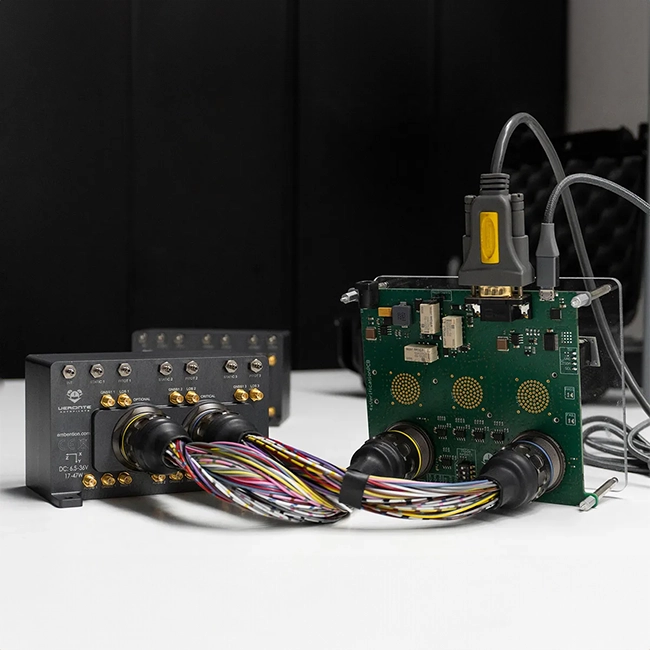

DO-254 Garantía de Diseño para Hardware Electrónico Aerotransportado. Establece un sistema de clasificación que permite separar los elementos de hardware en categorías simples o complejas, brindando pautas de diseño sistemáticas.

En otras palabras, el uso de estos estándares permite guiar los procesos de diseño para asegurar que tanto el desarrollo de software como hardware embarcado se realiza con las garantías necesarias para la certificación del sistema. Para ello, nos guiamos por el nivel de garantía de diseño (DAL), el cual utiliza un rango de 5 niveles. Actualmente contamos con el nivel de cumplimiento DAL-B, y estamos trabajando para pasar al nivel más alto, DAL-A.

Verificación y Validación

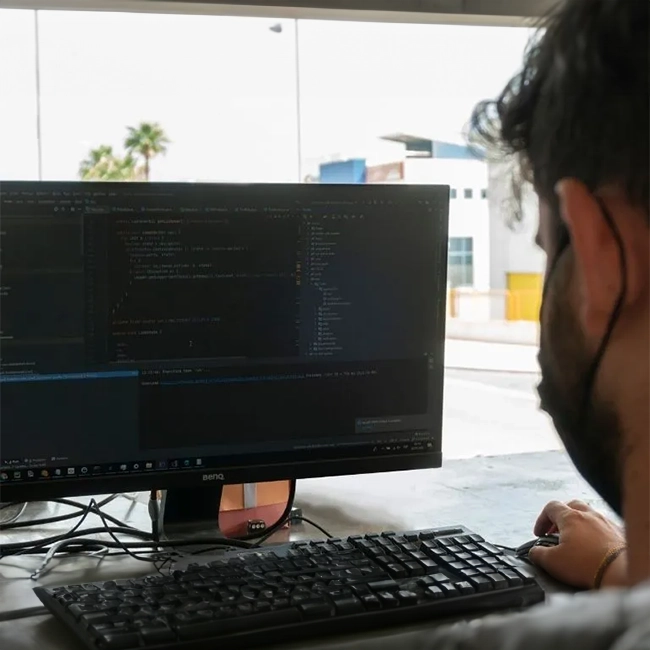

Embention cuenta con un departamento de Verificación independiente, este se encarga tanto de la verificación software como hardware en las distintas fases del proceso de diseño y desarrollo. Para ello cuenta con un entorno de desarrollo donde se incluyen requisitos, tests, resultados… y todas las herramientas necesarias.

Una vez en producción, se siguen estrictos procesos de Validación (ATP – Acceptance Test Procedure). Estos, definen tests para las distintas etapas de fabricación, incluyendo Ensayos de Estrés Ambiental (ESS) para la detección precoz de fallos. Los resultados de estos test quedan reflejados en los ATR (Acceptance Test Report).

La verificación del software sigue las pautas establecidas por el DO-178C. Como parte fundamental del estándar de desarrollo de software, conocido como el Método en V, se realizan Pruebas del Sistema para verificar los Requisitos de Alto Nivel (HLRs) y Pruebas de Unidad para verificar los Requisitos de Bajo Nivel (LLRs). Este conjunto de pruebas se ejecuta con cada lanzamiento de software.

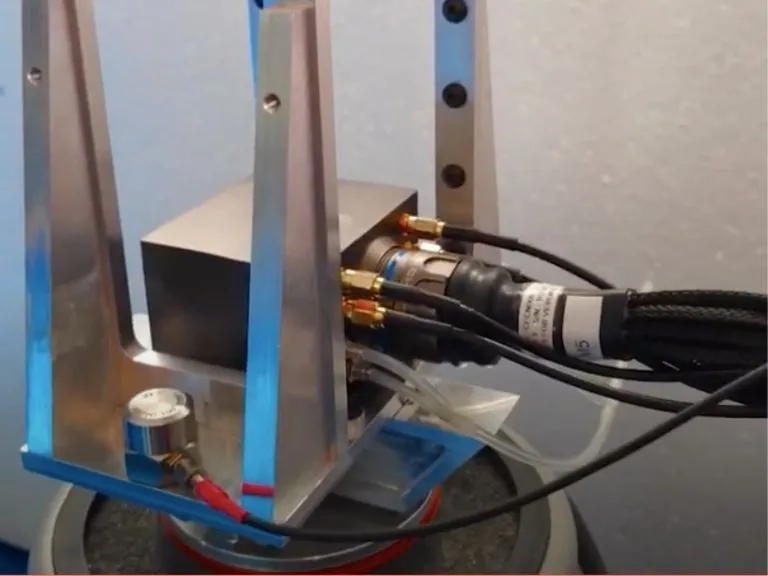

Ensayos Ambientales

Como parte de la verificación de sus diseños, Embention presta especial atención a los ensayos de calificación ambiental. Los estándares DO160 y MIL-STD-810, adoptados por la FAA y la EASA, son los más comúnmente usados. Se trata de métodos de prueba, que permiten medir de la influencia del medio ambiente sobre los productos. Estos ensayos se realizan en un entorno controlado, en un laboratorio, permitiendo garantizar la resistencia de los productos a ciertas condiciones ambientales (temperaturas, altura de vuelo, vibraciones…).

Las principales diferencias entre ambas normas radican en la industria, el proceso de adaptación y la consideración técnica para el entorno operativo real del equipo.

En Embention disponemos de equipos y laboratorios para la realización de ensayos de pre-cualificación de resistencia a vibraciones, temperatura, presión, IP67 y shock.

Roadmap

Investigación, desarrollo e innovación es nuestra clave al éxito. Entendemos que en el entorno VUCA en el que vivimos, es necesario adaptarse y predecir necesidades futuras.

Embention ha iniciado el proceso con la Agencia Europea de Seguridad Aérea (EASA) para obtener una ETSOA (European Technical Standard Order Authorization) y acreditarse como APDOA (Alternative Procedure to Design Organization Approval). Asimismo, la empresa se encuentra en trámites con la Agencia Española de Seguridad Aérea (AESA), para obtener la acreditación como POA (Production Organizatión Aproval). De esta forma, nuestros equipos podrán ser entregados una certificación (EASA-Form 1) que acredita que el equipo se ha desarrollado y producido bajo un standard Aeronáutico, reduciendo significativamente el esfuerzo necesario para la certificación de eVTOL y UAV.